[nonmember]This is an abstract of the full version – available for members – subscribe now![/nonmember]

Controlling Costs

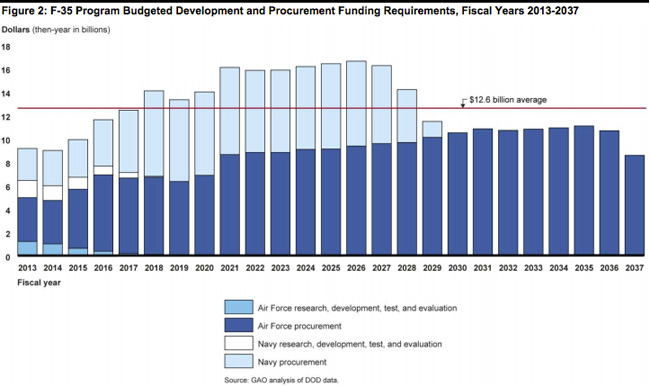

Lack of transparency about the flyaway and operational costs of the F-35 caused significant embarrassments to some of the strong supporters of the program. The cost of the F-35 has soared dramatically in recent years. From a fighter plane that would cost $69 million in 2001 the cost of a single Joint Strike Fighter soared to over $137 million in 2012, with more than twice that cost projected in operating costs. F-35 PEO Lt. General Bogdan claims these costs hikes are now over, and, with tighter control and better learning curve, the production cost of planes currently being manufactured is already dropping. According to JPO estimates confirmed recently by prime contractor Lockheed Martin, the flyaway cost of an F-35A is expected to be $85 million in 2020. Bogdan attributed the savings to tighter, more efficient management of the program, both at the JPO and the contractors, where personnel changes meant refocusing on performance efficiency and timely delivery.

[ismember]The next two production lots, Low Rate Initial Production (LRIP) 6 and 7 are currently in contract negotiation. “We believe we can have a negotiation settlement for lots 6 and 7 by the end of May 2013, followed by final contract award in June 2013.” Bogdan said that, for the first time in the program history, the two contracts will demand the contractors Lockheed martin and Pratt & Whitney to absorb all cost overrun. “Fixed-price-type contracts are planned for future F-35 aircraft and F135 engines procurements.” Bogdan declared. In the development phase, the program is also set to meet its goals.

The companies are beginning to share the risk of the program in LRIP 5 they took congressional mandate to take responsibility for production cost overrun. Bogdan mentioned that instead of retroactive compensation for cost overruns, incentive plans were set for Lockheed Martin, related to major program milestones – Lockheed Martin will receive up to $100 million incentive fees, allocated in three stages. For delivering phase 2B on time in 2015, the company will receive $40 million incentive fee. Similarly, they will get $25 million delivering phase 3I and finally, $35 million delivering 3F in 2017, by meeting each and every system requirement, on time and within budget. Bogdan stressed that the basic aircraft design is sound but added that he was concerned with the maturity and of future software releases scheduled for 2017.

[/ismember]

Bogdan cautioned that if reductions are made in procurement funding, fewer aircraft may be ordered in LRIP Lot 7 (FY13 budget) for the Navy and the Air Force. “While this would slightly lessen the cost burden imposed by concurrency, fewer aircraft in LRIP Lot 7 would increase the unit cost of the remaining aircraft in Lot 7.” Bogdan warned, “Our international partners are closely watching unit cost and are highly sensitive to cost increases.” He added.

Furloughs of civilian workers “will have immediate negative consequences,” he added. It would cause a reduction in testing and could reduce productivity by a third, he explained.

[nonmember]Members can read the full version of this article – subscribe now![/nonmember]

Other topics addressed by Bogdan were: