As vehicle manufacturers ramp up production of Mine resistant, Ambush Protected (MRAP) vehicles to address urgent requirement to increase troop protection, DOD is about to eliminate two vendors, and several vehicle variants, in an attempt to streamline the program. The new process is expected to solve conflicting demands for hard-steel supplies, reduce vehicle preparation time, including installation of government supplied equipment (GSE), testing and transportation.

While the Pentagon has yet to officially announce its decision, only three vendors will receive follow-on orders expected by early December 2007. According to Pentagon officials, the three vendors that already received the current orders will continue to get future business as they could sustain 1,200 vehicles per month. These vendors include International Military & Government (IMG) company and Force protection International (FPI) will both become exclusive providers for Category I (4×4) vehicles, while FPI and BAE Systems will continue to deliver the heavier Category II (mostly 6×6) vehicles. BAE Systems’ Category II (RG-33) vehicles were recently selected through a mini MRAP competition as the preferred design for 400 ambulance variants which the department is now purchasing. Sofar the Pentagon accelerated orders of Category I vehicles but since these vehicles will be more difficult to receive armor upgrades, the current preference is leaning toward heavier Category II platforms.

Streamlining the Family

The decision eliminates General Dynamics’ RG-31 Mod 5 from the race, as well as BAE Systems’ Stewart & Stevenson with its Caiman vehicle. Other drop outs earlier in the program included Textron systems (ASV), Oshkosh (Alpha) and Protected Vehicle International (Golan), some of these manufacturers actually delivered some vehicles under low-rate production orders but could not commit to mass production in time.

While the MRAP has already demonstrated its ability to meet the current threat in theater, the planned introduction of heavier, more effective armor protecting against Explosive Formed Projectile (EFP) IEDs will consume more payload capacity than most current MRAPs can offer. Some of the EFP armor enhancement concepts require significant excess payload capacity of the MRAP, though none of the current designs have as much payload capacity as the Defense Department would prefer. Category II vehicles, such as the RG-33 and Cougar currently offer the largest payload capacity in this class. The MaxxPro and 4×4 Cougar are also provide significant excess payload capacity to accommodate add-on armor but these would probably require more effort to eliminate some of the weight to meet the required threat level. Eventually, EFP enhancements are expected to become available and installed on all MRAP vehicles.

While the Pentagon tries to maintain MRAP configuration at a reasonable level, the vehicles are evolving and the next batches expected in 2008 (not yet included in current budget allocations), could include some enhancements that could render some of the MRAP II requirements obsolete. More changes are expected to reflect initial combat and operational lessons are provided by the troops using the first MRAPs. In fact, the program office allows the manufacturers of all current MRAP vehicles to bring them up to the MRAP II standard, in parallel to the MRAP II competition.

The MRAP production surge has already created conflicts in the demand for hardened and ballistic steel between MRAPs and other programs such as Strykers, Bradleys and Frag Kit 6 armor enhancements. A major limitation was the restriction DOD imposed on its suppliers, to buy hardened and ballistic steel only from US manufacturers. The department is currently processing a waiver that will temporarily allow vendors buying hardened and ballistic steel from foreign suppliers.

Gearing for Mass Production

During a briefing at the Pentagon, a senior defense official outlined the growing pace for MRAP production and fielding. By October 2007 the Pentagon placed ordered for roughly 8,800 MRAP vehicles. By early December, the Pentagon plans to release more orders for 6,500 additional vehicles, maintaining uninterrupted production through May 2008. If all DOD budget requests for additional $8.2 billion are answered, by the end of 2008 the US military expects to have over 15,274 MRAPs in theater, at an estimated cost of $24.5 billion (Fy-09) – covering acquisition and sustainment. DOD has drafted and is working with the White House to formally request the funds necessary to order those additional vehicles through a budget amendment.

At present, only 400 are in theater. Production rate has almost caught up with schedule but will have to increase rapidly in the months ahead. In September, only 309 vehicles were delivered, of which only about 101 were actually flown to Iraq. By the end of October 419 more are expected to be produced. The maximum available airlift capacity could deliver 360 vehicles per month. By November and December manufacturers are required to double and even triple production rate to meet the unofficial goal of 1,500 MRAPs in theater by year’s end.

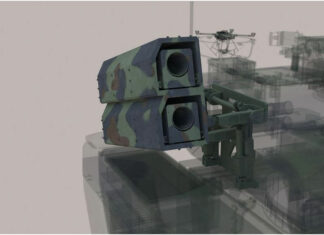

Expensive Delivery

Sofar only few hundreds were actually delivered. The reason for the prolonged process is not with production but due to the preparation of the completed vehicles for combat service. As they leave the production lines at the various manufacturers, MRAPs are transported overland to Space and Naval Warfare Systems Center (SPAWAR) at Charleston, SC where they are outfitted with weapon stations, CREW IED jammers, radios and a range of other equipment supplied by DOD through parallel acquisition programs. Each system must be tailored to each of the vehicle types through a particular installation, which requires prolonged evaluation, design and testing process, to ensure the vehicle can perform its intended mission without interference to other systems on board. This process usually takes months, even years but through the high priority MRAP acquisition it was trimmer to about three weeks. Vehicles which already went through this process and are more familiar to the teams at SPAWAR are processed more rapidly, typically within 10 days for a Cougar. The Pentagon expects that by reducing the number of MRAP variants and configurations, it could save significant time in outfitting the MRAPs for combat duty.

This process takes the MRAP as far as Charleston’s gate. Delivering the combat-ready MRAP to Iraq and Afghanistan already became the biggest challenge of the program, as these vehicles are too high for transportation inside the US Navy cargo ships (this limitation was overlooked in the MRAP preliminary design and is addressed with priority in the follow-on JLTV program). The only alternative is to fly them. The only benefit of this luxury option is the rapid delivery to the user. Each C-17 or C-5 can deliver only two vehicles. The Pentagon considers leasing Russian An-124 aircraft to accelerate delivery as they run out of airlift capacity by November 07.