The Naval Research Laboratory (NRL) has developed new methods to enhance the ballistic performance and penetration resistance of ballistic armor by the application of multiple layers of hard and soft materials in a process called ‘multi-ply’ armor.

The new armor consists of alternating layers of ‘elastomer’ (elastic polymer) and a harder material such as aluminum, ceramic, or hard polymer. Elastomeric coatings have been found to substantially increase the ballistic limit of underlying steel substrates. The benefits of such composition is the transition of impact from the elastomer rubber to the metal or ceramic glassy state.

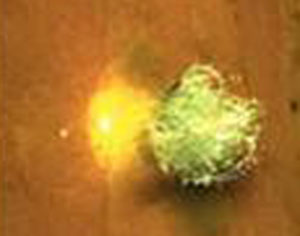

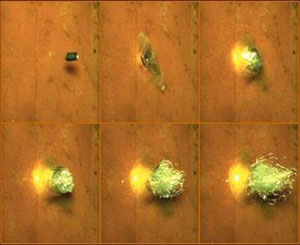

The multi-ply armor performance is enhanced with as few as six alternating layers. The layers can be attached to a thicker face plate or backplane, for additional protection. According to NRL researchers, the topographically structured front surface rotates pointed projectiles, combining projectile break up and pressure wave dissipation, thus enhancing penetration resistance.

By increasing ballistic resistance, protection element using multi-ply armor can become lighter than conventional armor, both as stand-alone armor or enhancement of existing armor. Overall, the multi-ply armor enhances ballistic resistance by 50% over standard steel armor at equal areal density. Therefore, it is significantly lighter than conventional armor with equal or better performance. Other advantages of the new armor are its modularity, flexibility and repairability, enabling body armor and and vehicle protection designers to tailor and optimize armor protection solutions to meet the specific user requirements.