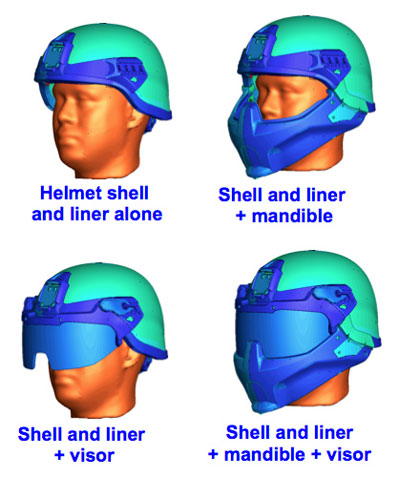

The US Army recently concluded a study evaluating the safety and survivability applications of different headgear carried by the modern soldier. The Natick Soldier Research, Development, and Engineering Center conducted the study called ‘Helmet Electronics and Display system — Upgradeable Protection’ (HEaDS-UP) as part of a multi-year effort to develop integrated headgear technologies for the Army and Marines. The program, managed by Mr. Donald R. Lee II, recommend potential upgrades for current helmets, improving the safety and integration with headgear, communications displays. Two modular headgear concept designs emerged from the process include improved eye and face protection which include the mandible and visor. Both provide fragmentation protection for the face. According to Don Lee, project engineer in the Headgear Thrust Area at Natick, the new new headgear parts will be provided as attachments parts can be added or removed in seconds. “Being able to don that (mandible and visor) protection when needed or being able to remove it when not needed is the big ‘wow’ factor,” he added. Other aspects of the program are evaluating improved ballistic materials, non-ballistic impact liner materials and designs, see-through and projected heads-up display technologies,improved hearing protection and communications.

The response we received that every Soldier that used these systems liked the prototype systems over their currently fielded system

Studies of combat injuries have shown that 72 percent of all the injuries to the head are to the face, indicating the need for improved protection that will also conform with the soldier’s ‘human factors’. “We were able to integrate the concepts during their normal training scenarios, and then following their training event, get feedback from them” Lee said. “It was quite overwhelming, the response we received that every Soldier that used these systems liked the prototype systems over their currently fielded system.”

Another aspect of HEaDS-UP project is understand and minimize the blast effect on the soldier’s head, a task Dr. David Mott—an aerospace engineer at the U.S. Naval Research Laboratory (NRL) have studied with his colleagues Ted Young and Doug Schwer . “Helmets are required to protect against a combination of threats, including ballistic and blunt impacts,” he says. The NRL research is helping to understand how blast, generated by explosions of IEDs, mines or impact of explosive anti-tank weapons, will effect the head protected by the helmet. The study explores how different shapes of helmets behave in an IED environment and its results would recommend the optimal protection for multiple threats situations.

These studies have shown that the mandible and visor are instrumental in protecting the wearer from those blast effects.

In 2008, NRL tested military helmets for the U. S. Marine Corps, in collaboration with Allen-Vanguard. The researchers set off an explosion near a mannequin, which had pressure sensors on its head. “After the initial wave hit, they were getting some additional spikes in the pressure on the forehead” Lee explained. The simulations showed the incoming wave of pressure can, as he says, “infiltrate the gap between the head and the helmet shell.” Sometimes called underwash, the effect has since been studied with various helmet types and reproduced by other investigators. Further experiments determined that pressure waves that infiltrate under the brim can then converge under the helmet. This causes “high pressures on the side of the head away from where the blast originated.” Trapped, the high pressure can then send a wave back toward the blast source, and this effect caused the forehead sensor in the 2008 experiments to “pick up a spike as that wave was exiting from under the helmet.”

When using just the helmet shell and suspension, the shock wave hits the face, creating a pressure spike on the eye. The wave also reflects from the suspension under the front of the helmet, causing a pressure spike on the forehead. “Now when you add the face shield, it keeps that direct hit from happening. A weaker wave still refracts around the bottom of the shield and reaches the face, but you significantly reduce the pressure on the forehead and the eyes by adding that shield.” Mott explained. If the simulation includes the mandible shield with the face shield, again, most of the initial wave is deflected, but according to Mott, there are side effects.

As the helmet variants got more complicated, so did the wave behavior. “When you start adding these extra pieces of equipment, you don’t always get what you expect,” says Mott. “Multiple shocks interacting with each other can amplify the pressure, as can reflections off the structures that are in the suspension pads or lining inside a helmet.”

Crew members looking out hatches discovered an unexpected benefit during evaluations. “When the Soldiers wore the prototype systems with the visor and mandible,” said Lee, “it was the first time that they weren’t eating sand and dust and rocks going down the road.” Ultimately, the program data will be transferred to Program Executive Office Soldier and the Marine Corps for decisions about what technologies should be fielded.

Assessing the helmets for personnel operating with armored vehicles, the study evaluated a single helmet for mounted and dismounted operations. According to Lee, mounted soldiers are provided two helmets. “They have their Combat Vehicle Crewman helmet and they have their Advanced Combat Helmet. So, if they dismount from the vehicle, they’re supposed to swap helmets. We’ve proven through our program that there can be one helmet for both mounted and dismounted Soldiers, which, I think, is a big deal. I think the program’s proven that a one-helmet system for ground Soldiers, whether they’re mounted or dismounted, can exist.”