Supacat is addressing the LPPV requirement by introducing the new Supacat Protected Vehicle (SPV) Series, enhancing the company’s successful range of high mobility vehicles. The 4×4 SPV 400 is offered as an optimal solution in Urgent Operational Requirement, for a Light Protected Patrol Vehicle (LPPV), replacing the Land Rover Snatch platform. For the LPPV bid Supacat is Prime Contractor and Systems Integrator responsible for the mobility platform, while NP Aerospace is Principal Sub-Contractor responsible for the protection and crew pod, as well as providing production resources.

The 4×4 SPV 400 Series concept, which carries a 2+4 crew and has a declared GVW of 7500kg, provides a useable payload of 1,500kg. A 6×6 SPV 600 Series sister platform is due to follow.

The new design combines a fully integrated protection system with the cross-country capable high mobility automotive platform, combat proven by operational vehicles such as the Jackal. The integrated protection system features a V-shaped hull for mine blast protection and a composite crew “pod” enhancing protection from kinetic threats, as well as blast.

The protection system developed in association with British armor expert NP Aerospace, includes mine-blast seats and configurable ballistic armor. The SPV survivability is predicated on “Fully Integrated Protection”, in which threat protection measures are integrated into the vehicle structure to achieve an optimized high protection, low weight solution. For example, the armored steel V-shaped chassis hull, manufactured as a single structure, with high ground standoff to provide integral blast protection. The axle assemblies are mounted in sacrificial sub frames, fore and aft of the hull, designed to blow off in the event of a wheel mine blast. The engine and transmission are installed in two separate assemblies, ensuring the crew pod is not impacted, should the front sub-frame detach. This modular approach also enables rapid in-theatre repair.

The composite crew pod sits over the hull, between the wheels, and utilizes the latest composite and ceramic armor systems to mitigate the operational threats at optimal weight.

The SPV chassis design features high articulation independent suspension, air spring units and tuned-for-purpose damping coupled to managed power transmission provides all terrain mobility and speed. A starter-generator provides substantial electrical power for all mission scenarios and the same Cummins engine and Allison transmission system matches the logistic footprint of Jackal and Coyote. The SPV400’s speed and all terrain mobility and maneuverability is comparable to Jackal and it is capable of 80mph on desert plain. Air suspension provides troops with a smooth ride, reducing crew fatigue.

The first SPV 400 prototype was subjected in December 2009 to two days of blast trials, simulating IEDs and large Vehicle Borne IED (VBIED) effect. The second and third SPV400 prototypes were completed at Supacat’s Dunkswell, Devon, facility in January 2010 and following initial company trials are participating in the UK MoD’s full trials program. A further two prototypes are being completed with one due to undergo further blast tests.

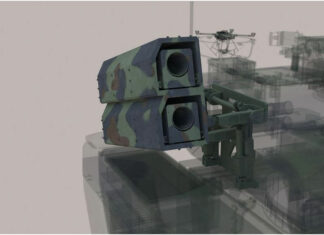

The international debut of the SP V400 was at Eurosatory 2010, where the most recent configuration of the vehicle was displayed. Sofar Supacat has built six prototypes, some are configured for the British LPPV requirement, and others used for blast testing. Supacat is also considering additional pod configurations, including a fire support version with a roof-mounted remote-controlled weapon station and an ‘open space’ pod, configurable for an armored ambulance, protected utility vehicle or a command and communications vehicle. A heavier version in a 6×6 configuration is also considered, to be fitted with a larger armored pod, carrying heavier payloads.