The new family of vehicles includes the mounted combat vehicle (carrying a 120mm cannon), a command and control vehicle, reconnaissance and surveillance vehicle, an infantry carrier vehicle, non-line-of-sight cannon (NLOS-C now in prototype stage), the non-line-of-sight mortar (NLOS-M) , a medical vehicle-evacuation and medical vehicle-treatment and recovery and maintenance vehicle. All eight vehicles will share a common platform, powertrain, suspension and tracks, chassis, and various systems such as sensors, active and passive protection, electronic and communications systems etc.

The total cost of the program is currently estimated at $160 billion. The lead systems integrator team (led by Boeing and SAIC) is contracted $21 billion for FCS System Development and Demonstration (SDD) phase spanning 11 years, from 2003 through 2014. Unlike individual programs of record, FCS is designed as an integrated system of systems, and the aggregate contract cost is not broken out by either individual pieces or platforms. One of the most innovative and essential elements of the program is that all of the systems have been designed from the outset to work together seamlessly.

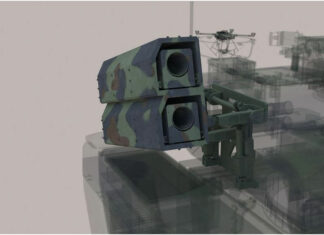

Army officials said they have adopted a phased development approach for FCS. This plan allows the Army to deploy the most mature and urgently required elements, while maintaining other systems in developmental phase, allowing the resolution of problems and technical challenges without disrupting the Army’s entire FCS modernization effort. There are three planned ‘Spinout’ phases for the program – Unattended sensors and small unmanned vehicles are included in the first Spinout. Sensors, active protection systems, a larger unmanned system and the FCS Battle Command Network are candidates for the second and third Spinouts.

The FCS family of vehicles is introducing many new capabilities to the Army. One of the most obvious, is the introduction of electrical propulsion for combat vehicles. “Every Manned Ground Vehicle (MGV), is going to be hybrid electric,” According to FCS Program Manager Maj. Gen. Charles Cartwright, during a session at the Association of the U.S. Army’s Institute of Land Warfare Winter Symposium and Exposition, each of the FCS Manned Ground Vehicles (MGV) will have an electrical power generation supporting 420 kilowatts, required to support the hybrid-electric propulsion and myriad of electronics systems on board. All eight MGV types will be powered by electric motors providing the traction drive. The motors will be powered by batteries, which are charged by side mounted high-power-density diesel generators. As technology matures, the diesel engine will be replaced by fuel cells for power generation, Cartwright said. The vehicle also uses active suspension system facilitating increased speed and agility and cross-country mobility, negotiating vertical and trench obstacles.

The first prototype of the Non Line Of Sight Cannon (NLOS-C), the lead vehicle in the FCS family of manned platforms is already in production; it is the first of five prototypes to be tested by the army beginning to be delivered this year. Another vehicle type, well underway is the Mounted Combat System (MCS). This vehicle will be the ‘tank’ of the FCS unit. MCS will have a crew of three – a commander/driver (common crew) and a gunner. The vehicle will carry a lightweight, low-recoil 120mm cannon, firing standard (line of sight) and beyond line of sight (MRM type) ammunition. The firing platform for the program’s Mounted Combat System 120mm cannon will enter production soon.

Elements of the common sensors to be used with each of the FCS MGVs were shown at AUSA Winter. The Multi-Function Radio Frequency system (MFRF) and Medium Range EO Infrared sensor System (MREO), both developed by Raytheon, are part of the sensor suite used on all FCS vehicles. These RF/EO elements will operate as ‘networked sensors’ connected through the C4ISR interface computer to provide the crew with real-time situational awareness, surveillance and targeting data. The same data could also be shared across the FCS combat team over the Common Operating Picture (COP) generated by the FCS ‘system of systems’ networking infrastructure.

Beside this family of vehicles, the FCS combat unit will field a number of unmanned systems, optimized for different combat roles. The largest unmanned element is the Multifunction Utility/Logistics and Equipment vehicle, (MULE), which was selected to be one of the candidates for the third technology ‘SpinOff’ scheduled for the next decade. This 2.5 ton unmanned ground vehicle (UGV) is designed to support dismounted and air-assault elements of FCS’ unit of action. There are three MULE versions in the planning – all are built by Lockheed Martin. These versions share a common mobility platform equipped with unique 6×6 independent articulated suspensions, in-hub electrical motors for each wheel, and a new suspension system enabling the MULE to negotiate rough terrain, far exceeding that of vehicles utilizing conventional suspension systems. The MULE will be equipped with one of three mission equipment packages – a transport, weapon and sensor/carrier and countermine platform. Two of the ground sensors are already in an advanced stage. The urban Unattended Ground Sensor (U-UGS) is designed to be a “left behind” asset for constant, 24-7 surveillance. Soldiers could leave an UUGS in a house that they cleared, and thereby eliminate the need for a Soldier to stay behind and monitor that structure. The UUGS would alert the Soldiers to the re-emergence of enemy combatants or insurgents.

Beside this family of vehicles, the FCS combat unit will field a number of unmanned systems, optimized for different combat roles. The largest unmanned element is the Multifunction Utility/Logistics and Equipment vehicle, (MULE), which was selected to be one of the candidates for the third technology ‘SpinOff’ scheduled for the next decade. This 2.5 ton unmanned ground vehicle (UGV) is designed to support dismounted and air-assault elements of FCS’ unit of action. There are three MULE versions in the planning – all are built by Lockheed Martin. These versions share a common mobility platform equipped with unique 6×6 independent articulated suspensions, in-hub electrical motors for each wheel, and a new suspension system enabling the MULE to negotiate rough terrain, far exceeding that of vehicles utilizing conventional suspension systems. The MULE will be equipped with one of three mission equipment packages – a transport, weapon and sensor/carrier and countermine platform. Two of the ground sensors are already in an advanced stage. The urban Unattended Ground Sensor (U-UGS) is designed to be a “left behind” asset for constant, 24-7 surveillance. Soldiers could leave an UUGS in a house that they cleared, and thereby eliminate the need for a Soldier to stay behind and monitor that structure. The UUGS would alert the Soldiers to the re-emergence of enemy combatants or insurgents.

Other unattended systems include the Tactical UGS (TUGS) – these ‘left behind’ assets are designed to support intelligence, surveillance and reconnaissance operations, providing persistent presence in area of interest to the unit. Two classes of UGS are in development – an urban and a tactical unmanned ground sensor. According to Gen. Cartwright, both have been delivered to the Army Evaluation Task Force at Ft. Bliss for Soldier Evaluation. Recent exercises conducted at Ft. Bliss also involved the Small Unmanned Ground Vehicle, (SUGV), and the ‘Class I’ Unmanned Aerial System (UAS). According to Gregg Martin, vice president and program manager, 25 SUGV and the 11 Class 1 UAS, (called Block 0) were delivered and are being used for testing, “We’ll deliver the rest of those new FCS systems in the April timeframe; they will then go through a Soldier evaluation around July.” said Martin. When the Army adjusted the FCS program, it dropped two unmanned aerial systems from the FCS systems lineup. As a result, specific roles, such as target designation functions (by laser) are to be integrated with the Class 1. Since the vehicle’s small size and limited payload capacity were inadequate for the new payload, the MAV required redesign to accommodate a bigger engine to account for the additional weight. The Class IV UAV, a joint Army-Navy program, will take delivery of its sensor package within the next two years, Martin said.

The software backbone of FCS is the ‘System of Systems Common Operating Environment’ (SOSCOE), a key element of the FCS network service layer that will be the operating system driving all FCS elements. “We’re at roughly 70 percent complete on the application build off of SoSCOE,” Martin said. SOSCOE is “performing very well on the application side. We’re about 40 percent through our software development, so we just completed integration of Build 1, which accounts for about a third of the software. The second phase (Build 2) will make another third of the software, and is broken into two parts, the first is scheduled to start to drop in the April 08 timeframe, and start the integration process throughout the summer.

Progress is made on the FCS network which is addressed in five specific layers: sensors, applications, services, transport and standards. In the transport layer, the Joint Tactical Radio System (JTRS) ground mobile radios (GMR) is the element required to interface and work with existing forces using current technology. “On radio side we have GMRs out in the field, working well,” Martin said. Current systems are pre-engineering developmental models and will be followed by more mature systems in late 2009. Other JTRS radios to be included in the system are handheld, manpack, and small form-fit radios that will be integrated into the various unmanned systems. Currently the Small Form Fit (HMS) radion is being integrated with the Class 1 MAV with testing scheduled to begin in Summer 2008.