General Dynamics Land Systems-Canada is teaming with BAE Systems Ground Systems Division, to offer vehicles to the Mine Resistant Ambush Protected (MRAP) program. GDLS Canada will provide the program management and logistic support while South African based BAE Systems Land Systems OMC will manufacture the vehicles in BAE Systems’ facilities in York, Pennsylvania. For the MRAP program the team is offering the RG- 31 Mk5, the latest version of the highly successful RG-31 vehicle family, offering significant increase in power and payload while enhancing mine blast resistance and protection against both improvised explosive devices and ballistic threats. General Dynamics Land Systems-Canada is providing vehicles for both Category I and Category II requirements of the MRAP program under this contract.

Force Protection, Inc. and General Dynamics Land Systems are forming a joint venture to offer the Cougar 4×4 and 6×6 armored vehicles for the Mine Resistant Ambush Protected (MRAP) vehicle program, a U.S. joint services program being managed by the U.S. Marine Corps. The joint venture was formed to offer Force Protection’s Cougar 4×4 and 6×6 armored vehicles as an MRAP solution. The joint venture called Force Dynamics will include an experienced team in program management, systems engineering, production and service support from both Force Protection and General Dynamics. The companies are already cooperating in the fabrication of the armored capsule for the Cougar.

Force Protection, Inc. and General Dynamics Land Systems are forming a joint venture to offer the Cougar 4×4 and 6×6 armored vehicles for the Mine Resistant Ambush Protected (MRAP) vehicle program, a U.S. joint services program being managed by the U.S. Marine Corps. The joint venture was formed to offer Force Protection’s Cougar 4×4 and 6×6 armored vehicles as an MRAP solution. The joint venture called Force Dynamics will include an experienced team in program management, systems engineering, production and service support from both Force Protection and General Dynamics. The companies are already cooperating in the fabrication of the armored capsule for the Cougar.

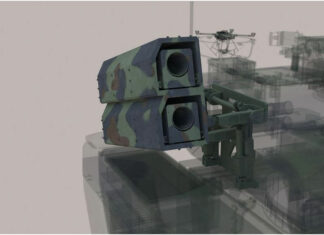

The 1st Marine Expeditionary Force requested 1,169 MRAP vehicles. The program calls for a commercially available off-road and highway capable armor and mine protected vehicle, configured for personnel, cargo and litter transportation. The vehicle should have a payload capacity of 5000 lbs, and will be able to carry 6 – 10 troops. The vehicle will be configured to carry existing gunner protected turrets or remotely controlled weapon stations, enabling the gunner to load, operate and engage targets from fully protected positions. To improve recovery after mine damage, the vehicle will be built of modular components that could break away from the vehicle in the case of a blast. Its energy absorbing seats should be capable of withstanding the accelerative effects of mine blasts.

The 1st Marine Expeditionary Force requested 1,169 MRAP vehicles. The program calls for a commercially available off-road and highway capable armor and mine protected vehicle, configured for personnel, cargo and litter transportation. The vehicle should have a payload capacity of 5000 lbs, and will be able to carry 6 – 10 troops. The vehicle will be configured to carry existing gunner protected turrets or remotely controlled weapon stations, enabling the gunner to load, operate and engage targets from fully protected positions. To improve recovery after mine damage, the vehicle will be built of modular components that could break away from the vehicle in the case of a blast. Its energy absorbing seats should be capable of withstanding the accelerative effects of mine blasts.

The armor protection of the vehicle include mine protection and ballistic protection of the full, roof protection from overhead airburst and side protection against fragmentation and blast. The transparent armor windows will have protection level equal to or greater than that of the ballistic armor on the vehicle, and will have built-in gun-ports. RPG protection could also be an option.