Excessive weight and limited mobility always exacerbate the weak points of personal body armor suits, demanding users and developers to agree and compromise on an acceptable balance between cost, weight, mobility and protection. Aiming always for ‘best possible protection’, meaning NIJ Level IV, does not make sense in terms of overall weight, as it results in personal armor suites that weigh more than the soldier can carry.

Sometime, this balance means not to decide at all – for example, British troops are deployed with two types of armor vests, enabling soldiers to choose the right kit for the particular mission, balancing between protection and mobility. US troops are using the Interceptor Body Amror (IBA) which went through several improvements since it was introduced and went into combat in Iraq and Afghanistan.

The Interceptor’s outer vest is produced by Point Blank, while the add-on inserts are produced by several companies, including Honeywell, Ceradyne, Armor Holdings, ArmorWorks and others. At AUSA 06 the Armor Holdings introduced the LIMBS system, Lightweight Integrated Mobility Body Armor System. LIMBS provides enhanced protection to the shoulders, Bicep and Thigh while offering 25% less weight compared to existing systems. Its ergonomical design improves mobility, comfort and performance. The suite combines a shoulder-Bicep system.

The Interceptor’s outer vest is produced by Point Blank, while the add-on inserts are produced by several companies, including Honeywell, Ceradyne, Armor Holdings, ArmorWorks and others. At AUSA 06 the Armor Holdings introduced the LIMBS system, Lightweight Integrated Mobility Body Armor System. LIMBS provides enhanced protection to the shoulders, Bicep and Thigh while offering 25% less weight compared to existing systems. Its ergonomical design improves mobility, comfort and performance. The suite combines a shoulder-Bicep system.

Modern body armor designs are harnessing advanced manufacturing techniques, such as new bonding materials, flexible steel fiber meshes, ceramic-composites matrixes and molded glass-ceramics to develop lightweight personal protection systems that can better fit the human body, offering ‘assault vests’ style body armor that can be integrated with the soldier’s load-bearing vest. Typical of this new generation of body armor is the assault vest developed by Kata Vitec, and integrated as part of the latest version of the IDF Hashmonai bullet-proof gear. In the original design, this vest utilized a ‘clamshell’ formation made of two High Density Polyethylene (HD-PE) composites formed through pressing methods to better fit the human body, allowing unrestricted movement with full protection gear. The latest version of this ‘Anatomic’ assault vests combines advanced inserts made of glass ceramic materials, molded to match the same shape at a much lower cost and weight. Currently available at NIJ level III+, the producer of the new glass ceramic plate is currently working on an enhanced version that will meet Level IV requirements offering similar weight and cost advantages.

A different flexible armor design is implemented in Pinnacle Armor’s Dragon Skin body armor, utilizing flexible armor made up of bullet proof ceramic ‘leaves’, creating a flexible layer shaped like fish scales.  This armor is claimed by the producer as superior to the US Army standard Interceptor body armor, with certified protection Levels of NIJ level III and IV. Ceraflex, manufactured by Ares Composites uses a Ceramic matrix bonded on flexible aramide pre-pregnated backplane to offer shaping flexibility while retaining the high ballistic performance of ceramics. Monolithic ceramic plates can be shaped into curved shapes by complex pressing process, which reduce protection level. Therefore, these tiles have inherent limitation as to the curvature they can provide. Due to its matrix design, Ceraflex does not have this limitation and retains effective protection against Level III multiple 5.56 and 7.62mm threats over the entire area. According to the manufacturer, when configured for level IV protection, the tile can stop AP threats including modern ammunition with tungsten carbide core. Due to the homogeneous (seamless) matrix composition, Ceraflex can stop a wider ammunition range than ceramic tiles at 10 – 30% of the weight of comparable monolithic ceramic tiles.

This armor is claimed by the producer as superior to the US Army standard Interceptor body armor, with certified protection Levels of NIJ level III and IV. Ceraflex, manufactured by Ares Composites uses a Ceramic matrix bonded on flexible aramide pre-pregnated backplane to offer shaping flexibility while retaining the high ballistic performance of ceramics. Monolithic ceramic plates can be shaped into curved shapes by complex pressing process, which reduce protection level. Therefore, these tiles have inherent limitation as to the curvature they can provide. Due to its matrix design, Ceraflex does not have this limitation and retains effective protection against Level III multiple 5.56 and 7.62mm threats over the entire area. According to the manufacturer, when configured for level IV protection, the tile can stop AP threats including modern ammunition with tungsten carbide core. Due to the homogeneous (seamless) matrix composition, Ceraflex can stop a wider ammunition range than ceramic tiles at 10 – 30% of the weight of comparable monolithic ceramic tiles.

Flexible Armor

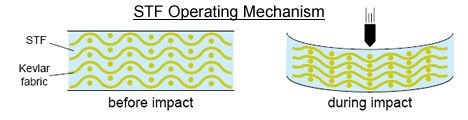

A new “liquid armor” could be the solution for protecting the limbs, which cannot be protected by standard, rigid body armor. Conventional ballistic fabrics impregnated with STF effectively resisted penetration from an ice pick that would otherwise easily penetrate the fabric. In addition, such materials demonstrated reduction in “back face deformation”, hinting on their ability to reduce the blunt trauma effect resulting of high energy ballistic impacts.

A new “liquid armor” could be the solution for protecting the limbs, which cannot be protected by standard, rigid body armor. Conventional ballistic fabrics impregnated with STF effectively resisted penetration from an ice pick that would otherwise easily penetrate the fabric. In addition, such materials demonstrated reduction in “back face deformation”, hinting on their ability to reduce the blunt trauma effect resulting of high energy ballistic impacts.

In 2006 Armor Holdings became the sole commercial provider of STF technology in applications related to body armor vests and extremity protection, helmets and gloves for protective use worldwide. Dr. Tony Russell, Chief Technology Officer for Armor Holdings, Inc., explains: “Going back to the Middle Ages, developing armor has involved a constant balance between the need for protection and the need for comfort, flexibility and light weight. Rarely do the words ‘flexible’ and ‘armor’ get used in the same sentence, but this new technology has the potential to unlock entirely new and better solutions that will leapfrog to the next generation of armor and other lifesaving equipment.” Armor Holdings plans to offer the field STF based armor designed for the military market later in 2007. The Russians are also studying applications of liquid armor. The Military and Industry Venture Fund of the Sverdlov Region is studying the application of liquid Armor for vehicles, boats, helicopters in addition to body armor vests. Their design goals are to improve the level of protection while minimizing weight increase.

In this series Defense Update covers the following topics:

- Body Armor Suites

- Ergonomic Body Armor Designs

- Ballistic Helmets

- Physiological and Physical Challenge of Body Armor

- Eyewear Protection for the Warfighter

- Tactical Benefits of Laser Eye Surgery (LASIK / PRK)

- Cooling with Phase Change Materials (PCM)

- Improving the Combat Survival Rate Among the Wounded

- Load Carrying Systems for the Infantry