February 25, 2010: The US Army TACOM Life Cycle Management Command (LCMC) released today the Request for Proposal (RFP) for the Technology Development (TD) phase of the Ground Combat Vehicle program, designed to develop the next generation Infantry Fighting Vehicle (IFV) for the U.S. Army. The Army has set aside $645 million in this year and FY11 budget to fund the program.

The development phase will span over seven years and include three phases. Through the 27 months first phase (TD) the Army will be able to test, evaluate and demonstrate Critical Technology Elements (CTE’s) and formalize a set of requirements, for the subsequent full system design phase. Later this year, the Army is planning to issue up to three cost-plus contracts for the TD phase, to be selected, used on ‘best value’ contracting strategy. This phase will evaluate three concurrent developments, designed to meet the Army’s requirements, based on relatively mature technologies (TRL 6+); prototypes of specific subsystems will also be evaluated. This phase will culminate with the preliminary design review and Milestone B scheduled for early 2013.

The next phase will be Engineering & Manufacturing Development (EMD), screening out one of the three TD contractors, based on ‘best value’ represented by the three proposals. This phase will include the prototype fabrication, ballistic survivability testing of armor coupons, turret and hull, followed by the delivery of first prototypes by the end of 2014. These vehicles will go through extensive safety, mobility and limited user tests, providing operational insights about the new platform’s performance.

By early 2016 the prime contractor for the Production and Deployment phase (P&D) will be selected. First production vehicles are scheduled to be delivered 7 years from the initial award of the TD contracts.

Initial operational capability of the first battalion, fielding 29 IFVs is expected by mid 2018, with a full brigade fielded within a year. In total, about 62 vehicles will be produced through the Low Rate Initial Production (LRIP) to equip combat units by the time the GCV enters full rate production in mid 2019.

The Army hasn’t limited the participation of international companies, although traditionally the Pentagon requires domestic prime contractors for programs of such magnitude. It is anticipated that at least some international cooperation could be achieved, at least regarding the survivability suite of the vehicle. While the Army has spent hundreds of millions on the development of advanced, lightweight armor for the FCS family of vehicles, these armor solutions have not yet reached maturity level required for the TD phase, at least regarding the threat levels considered for contemporary conflicts. Therefore, U.S. manufacturers could be relying on foreign technology to achieve the required protection. In past programs, including the Bradley reactive armor, the Stryker’s RPG protection and some of the MRAP vehicles, the U.S. is relying on foreign armor solutions, and the GCV could follow suit as well.

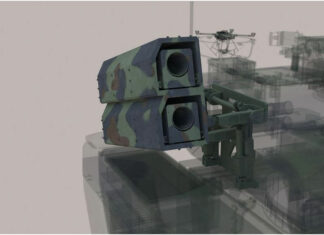

In its directives for industry about the GCV survivability suite, the Army has not specified a mandatory to of hit avoidance (soft and hard kill systems – APS) or advanced lightweight armor, developed by the Army, except for the Base Level EFP armor, Level 1 kinetic armor for front, skirts and roof and Level 1 EFP armor. All other protection means are open for suggestion by industry. The Army has recently completed the evaluation of seven APS systems – three domestically developed systems and four provided by international suppliers. This evaluation was mandated by congress.