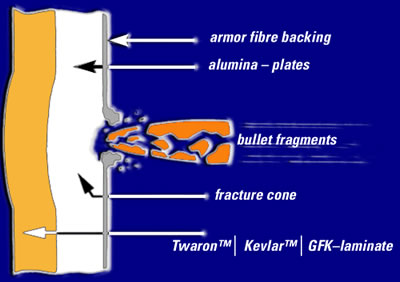

Conventional steel armor defeats an incoming projectile by reducing its kinetic energy through ductile deformation. In a composite, ceramic based armor, a different process is employed. Firstly, the hit-on the strike (top) surface causes significant deformation to the projectile, increasing its cross section. Its kinetic energy is reduced as the bullet is fragmentized on shattering the tile’s hard surface. The residual energy of the smaller fragments is absorbed by plastic or elastic deformation within the backing of the armor tile. A typical composite protection tile weighs half the weight of steel plate that would provide the same level of protection. In spite of its weight advantage significant drawbacks of the composite armor remains in its limited capability to protect against multiple hits (as the ceramic element does not retain the same physical properties after disintegration). To improve the armor performance in multi-hit scenarios, smaller ceramic elements are used. In a mosaic or matrix modules, special cylindrical or ball shaped ceramic pellets are used, reducing the affected area to few centimeters, small enough to protect against repeated impact on adjacent surface.

Conventional steel armor defeats an incoming projectile by reducing its kinetic energy through ductile deformation. In a composite, ceramic based armor, a different process is employed. Firstly, the hit-on the strike (top) surface causes significant deformation to the projectile, increasing its cross section. Its kinetic energy is reduced as the bullet is fragmentized on shattering the tile’s hard surface. The residual energy of the smaller fragments is absorbed by plastic or elastic deformation within the backing of the armor tile. A typical composite protection tile weighs half the weight of steel plate that would provide the same level of protection. In spite of its weight advantage significant drawbacks of the composite armor remains in its limited capability to protect against multiple hits (as the ceramic element does not retain the same physical properties after disintegration). To improve the armor performance in multi-hit scenarios, smaller ceramic elements are used. In a mosaic or matrix modules, special cylindrical or ball shaped ceramic pellets are used, reducing the affected area to few centimeters, small enough to protect against repeated impact on adjacent surface.

The mosaic of small tiles or pellets is embedded in a matrix of epoxy; additional layers of composite materials or rubber (RAMTECH) are used, to seal the armor tile from both sides. As the tile is attached to the ballistic steel or aluminum armor of the vehicle’s hull, the overall protection of the vehicle is increased dramatically. Future applications of advanced composite structures configurations are currently in research phase and include ceramic-ceramic, ceramic – metal and ceramic – carbon elements.

Additional parts of this article:

- Lightweight Armor Protection for Combat Vehicles

- Advanced Armor for Future Combat Systems

- Ceramic Armor Materials

- Ceramic & Composite Armor Protection Principles

- Vehicle Armor Protection