Snecma, the French engine manufacturer of the Safran group is working on an ‘open rotor’ engine that promises to cut fuel consumption and CO2 emission levels, and reduce acoustic signature powering the passenger airplanes in the 2030s.

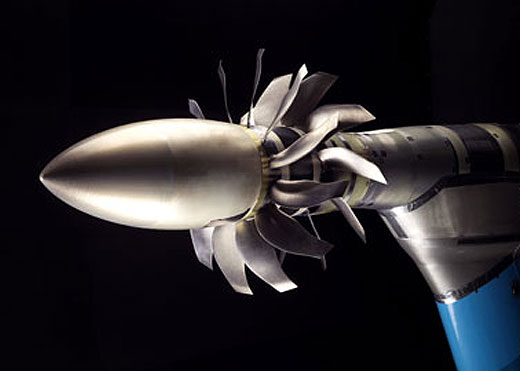

The goal of the current research is to test a jet engine that consumes 30% less fuel than today’s powerplants. This new type of engine comprises two distinct parts: a conventional gas generator, and a turbine driving two counter-rotating, unducted fans that will propel the aircraft.

“An aircraft engine’s efficiency and consumption depend on the amount of air the fans draw and eject at slow speeds,” Snecma (Safran) Research & Technology Director Pierre Guillaume points out. “With the open rotor, we will be able to considerably increase that drawn air flow because we won’t have any ducting around the fans. And that will improve consumption and cut CO2 emissions.” In addition to fuel saving, the new engine will contribute to cutting CO2 emissions, a goal supported by the Clean Sky European initiative and the fuel-consumption and CO2 emission goals for future air traffic, set by the Advisory Council for Aeronautical Research in Europe (ACARE).

There are still a number of challenges to tackle, starting with noise. “We are confident about this issue, after the tests we ran in July 2013 in the ONERA wind tunnel in Modane,” Guillaume explains. “The open rotor’s noise level should be similar to the LEAP’s, i.e. 10 dB below the engines flying today.” These first tests, on a 1:5 scale model, led to a new campaign at the end of the year, to test the fans’ aeronautical performance. “We measured the twinned fan thrust to make sure it matched our calculations,” Pierre Guillaume adds.

Following the scale down model test conclusions the team is now focusing on building a full-size prototype. “That prototype should be ready for the bench by the end of 2015. This stage will be particularly complex because all the rear components rotate. We are going to be able to test the propulsion module with the reduction gearbox, control units and control system governing blade pitches. We will use the gas generator on the M88, the engine powering the Rafale, which we are already manufacturing today,” Snecma’s R&T Director added.

The team building this demonstrator includes Snecma, Avio Aero (GE), GKN and Aircelle (Safran). The prototype should start its first flight tests on an Airbus A340 in 2019. “If we want to stay on track for entry into service in 2030, we need to move fast, because certifying this new engine generation will take time—and take extensive discussions with the relevant authorities,” Pierre Guillaume concluded.