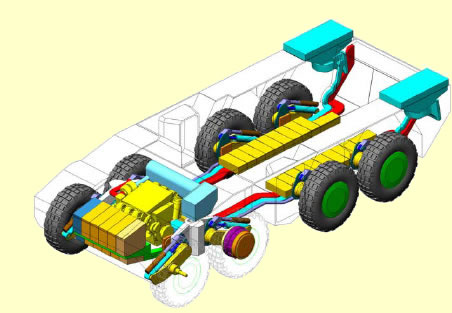

There versions of hybrid-electric vehicle propulsion systems are currently evaluated under different programs. The “Series Hybrid Electric Drive (HED)” decouples the diesel engine from the wheels, driving each axel or wheel by an electrical motor. Typical examples of Series HED are the AHED and SEP combat vehicles, developed for future armored vehicle programs, and the future tactical truck (FTTV). This configuration is viewed as more suitable for weapon carriers, missile launchers (such as HIMARS, LOSAT, Patriot and MEADS). Elimination of the heavy mechanical drive train reduces the total weight of the vehicle and enables more flexible “packaging” of a mission system. Further advantage is the ability to be stationed on “silent watch” for extended periods or driven in “stealth” movement (battery powered). This feature is absent from comercial ‘hybrid cars’ applications, due to the high cost of battery and motors, required for extended propulsion of the vehicle.

The “parallel hybrid electric” retains the mechanical link from the engine to the wheels and augments it with electrical power regenerated when the vehicle is braking or decelerates. A “hybrid hydraulic” mechanism stores energy in hydraulic recuperators, rather than chemical batteries. Although parallel hybrid is heavier than serial HED, it offers the redundancy advantage of a conventional, mechanical link when operating a heavy duty truck. HED can be applied into existing vehicles (“plug-in” – Humvee, HEMTT-A3, FMTV) or implemented in the basic design of new vehicles (RST-V, FTTS, FCS)

Additional parts of this article:

- Military Applications of Hybrid Cars and Trucks

- Technical Principles of Hybrid Electric Drive

- Plug-in Hybrid Electric Vehicles (HED) the Humvee example

- Hybrid Electric Vehicles (HED) Powered Trucks

- Hybrid Electric Drives (HED) For Armored Fighting vehicles

- Power Sources and Batteries for Hybrid Electric Drive (HED) Vehicles