A first hybrid-electric tracked armored vehicle developed by the U.S. Army’s National Automotive Center and BAE Systems (formerly United Defense) was the hybrid-drive 15-ton M-113 prototype. The vehicle’s battery power was used to provide transient power needs, on acceleration, steering and climbing. When stationary, the vehicle can generate about 200 kilowatts of electricity and function as an auxiliary power unit.

Relative to conventionally powered M113A3 the hybrid powered vehicle would produce about 500 horsepower in acceleration, versus only 275 horsepower for the most powerful M113A3. The vehicle developed the augmented power by supplementing the conventional engine’s generated power with the energy stored in the battery pack. The batteries stored the energy produced when the brakes was applied.

Relative to conventionally powered M113A3 the hybrid powered vehicle would produce about 500 horsepower in acceleration, versus only 275 horsepower for the most powerful M113A3. The vehicle developed the augmented power by supplementing the conventional engine’s generated power with the energy stored in the battery pack. The batteries stored the energy produced when the brakes was applied.

Most of the modern armored vehicles development programs, including the US Army FCS, British FRES, French BOA EBRC and Swedish SEP are based on HED technologies. Most programs are evaluating technology demonstrators prior to final decision on the type and configuration of the automotive system. Among these demonstrators are AHED, developed by General Dynamics, SEP, produced by BAE Systems land Systems, and TTS, produced by BAE Systems (formerly UDLP).

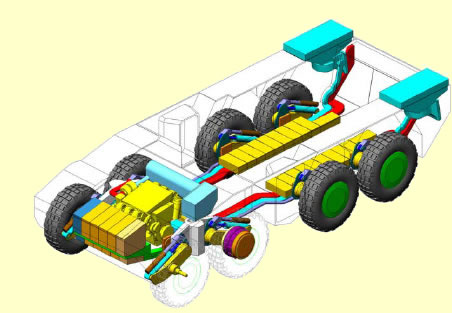

AHED, an 8×8 wheeled vehicle has been demonstrated following several years of field testing, accumulating over 4,200 km of road and cross-country testing. It is currently undergoing testing in support of the British MOD FRES evaluation phase. The Swedish SEP program includes both tracked and wheeled versions. The wheeled version, called “SEP-Wheeled” vehicle has three axles and uses 6×6 drives. The vehicle uses two engines driving an electric transmission, powering each wheel by a 100 kW maximum power permanent magnet, in-hub electric motors. The motors are fitted with a two speed reduction gear. This design offers high redundancy and survivability when operating in combat conditions.

The tracked version of SEP is fitted with special rubber bandtracks (already used with Bv206 articulated carriers) rather than conventional steel link tracks. These tracks are lighter, quieter and have a operational life of about twice that of an equivalent steel linked track. The new bandtracks have a lower rolling resistance and are operating more efficiently with the electric transmission systems, yielding higher fuel efficiency. Another unique design feature is the underframe mounted suspension. This spaced outer layer gives enhanced protection against mines. The SEP vehicle can withstand a 7 kilogram TNT explosion under a track.

Similar techniques are evaluated for the Transformation Technology Demonstrator (TTD), developed by BAE Systems. This demonstrator uses hybrid electric drive combines battery power with a 250hp diesel generator to deliver 450hp instantaneously, enabling faster acceleration than any existing combat vehicle. When used in stealth mode, the TTD has a 10-mile range on battery power, producing silent operation. When stationary, the TTD can stand “silent watch” for more than 30 hours – both features will be of significant value for Future Combat Systems (FCS) applications. The TTD is designed for C-130 transportability and could travel up to 600 miles without refueling. Its band track provides three to five times the current track durability, significantly reduces noise and vibration, improves the ride and requires little or no maintenance. The company cooperated with General Dynamics in the development of a hybrid-electric FCS-W (Future Combat Systems— Wheeled) demonstrator which can travel 5 miles per hour for 30 minutes on level ground using only stored electric power.

HED automotive technology is used in robotic ground vehicles, an example was the Spinner 6×6 HED powered Unmanned Ground Combat Vehicle (UGCV), which demonstrated up to 14 days missions and 450km range without refueling. The vehicle is powered by a 60Kw turnine, driving an electrical generator, feeding liquid cooled 30Kw hub UQM motors. The vehicle uses Lithium Ion SAFT battery to deliver up to 18 Kw/hour for silent operation.

Additional parts of this article:

- Military Applications of Hybrid Cars and Trucks

- Technical Principles of Hybrid Electric Drive

- Plug-in Hybrid Electric Vehicles (HED) the Humvee example

- Hybrid Electric Vehicles (HED) Powered Trucks

- Hybrid Electric Drives (HED) For Armored Fighting vehicles

- Power Sources and Batteries for Hybrid Electric Drive (HED) Vehicles