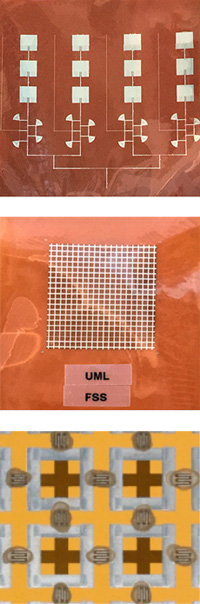

Researchers at a Raytheon-sponsored lab at the University of Massachusetts, Lowell, have developed a new type of “ink” that can be used to “print” tunable microwave components that form the key elements of radar systems. Elements printed with the new “functional ink” form a specific type of capacitor called a voltage-variable capacitor, or ‘varactor’ – an essential electrical component of modern radar systems.

“Printable devices such as those phase shifters and filters will lead to much cheaper and faster manufacturing processes”, says Christopher McCarroll, who co-directs the Raytheon UMass-Lowell Research Institute. The bottleneck has been that high-performing electronic devices generally rely on materials requiring high-temperature manufacturing, which is not compatible with plastic.

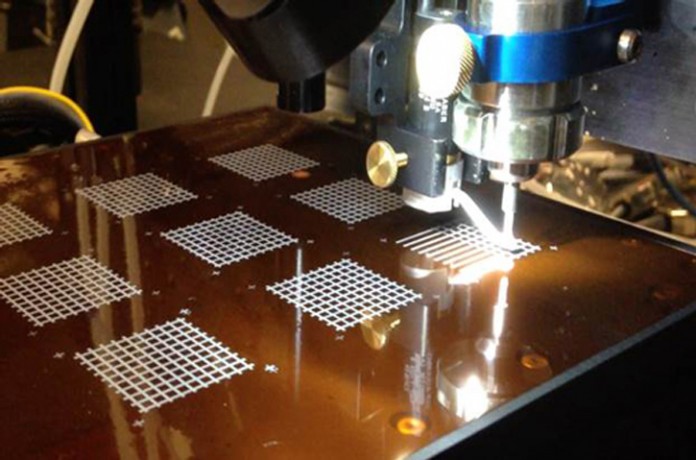

Researchers have already developed conductive inks, often containing metal nanoparticles, that can be processed at relatively low temperatures. Inks that would yield tunable devices for radar must contain materials with certain electrical properties that can be adjusted by applying voltage. The new ‘Functional Ink’ suspends those particles in a thermoplastic polymer, enabling simple deposition and curing at temperatures low enough to be compatible with certain plastics. To make the two devices, the group currently uses an aerosol-jet printer, which employs streams of gas to precisely deposit conductive ink made of silver, and another printer that relies on tiny vibrations to dispense the new ink.

Researchers hope the new printed devices could combined with the high-powered computer chips in the future, forming complete radar systems.

Read the full article by By Mike Orcutt on MIT Technology Review