Various types of appliqué armor were displayed at AUSA 2006, used for enhancement of armor protection of soft and armored vehicles. Among the systems displayed was the LAST armor system developed by Foster Miller. LAST uses a unique hook-and-loop fasteners similar to the Velcro, but five times stronger, enabling rapid application, removal and replacement of external (ceramic) armor tiles and external (spall liners) armor. A different type of protective material was introduced by Boeing. The company displayed a new range of lightweight composite based materials acquired as part of the recent acquisition of Macro Industries Inc. The new armor uses aramid fibers, specially weaved to form a lightweight structure that is thinner and weighs less than comparable panels made of Kevlar. The basic structure effectively protects against 0.5 Caliber Ammunition and can be upgraded to defeat even 14.5mm rounds.

A different type of protective material was introduced by Boeing. The company displayed a new range of lightweight composite based materials acquired as part of the recent acquisition of Macro Industries Inc. The new armor uses aramid fibers, specially weaved to form a lightweight structure that is thinner and weighs less than comparable panels made of Kevlar. The basic structure effectively protects against 0.5 Caliber Ammunition and can be upgraded to defeat even 14.5mm rounds.

A range of advanced armor materials was displayed by General Dynamics Armament & Technical Products (ATP) and GD Land Systems divisions. GD-ATP has recently expanded its ass-on reactive armor protection offering beyond the Bradley, for which it relied on the reactive armor kits produced by RAFAEL. GD is now supplying reactive armor suites for the US Army Stryker and M-1A2 Abrams tanks. GDLS has also displayed advanced armor concepts, including the composite/ceramic LIBA matrix known as Surmax, providing appliqué frontal protection for the U.S. Army Stryker vehicles.

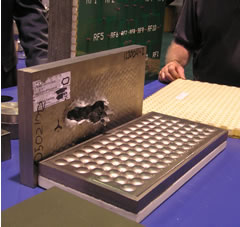

Other armor designs utilize aluminum sheet formed honeycomb, embedded with Silicon Carbide pellets, creating a lightweight armor capable of defeating multiple hits of high speed (APFSDS) 25mm armor-piercing ammunition fired at short range.  Other lightweight armor materials displayed were Titanium carbide and Boron carbide ceramic modules. A different concept demonstrated a composite armor element embedded with electronic circuits forming antennas for communications and sensor applications.

Other lightweight armor materials displayed were Titanium carbide and Boron carbide ceramic modules. A different concept demonstrated a composite armor element embedded with electronic circuits forming antennas for communications and sensor applications.

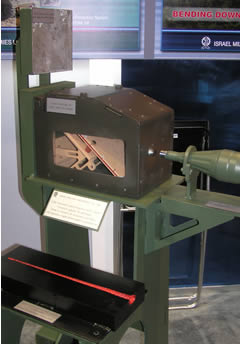

A new type of Electro-Magnetic Armor (EMA) is under development by SAIC. This system incorporates modules of layered conductive plates applied to the vehicle’s surface. Conducting plates within the modules are charged to high voltage, and, as a shaped charge jet passes through the electrified area between the conducting plates, it draws a large current from a capacitor bank, dispersing before it hits the vehicle’s surface. To maintain the armor fully charged at all time, EMA systems will require using high energy density components and advanced energy storage technologies. SAIC has already tested EMA on combat vehicles, against multiple, live fire threats. EMA is proposed for both future combat vehicles, equipped with hybrid electric power systems and as an upgrade for current platforms. Start < Page 3 of 5 >